- Home

- Products

- Laser Cutting Machines

- Co2 Laser Engraving Machine

- Laser Marker

Laser cutting machine

- Fiber Laser Welder

- YAG Adwords Welder

Laser Welder

- About us

- Customer praise

- News

- Contact us

Adopt the world top laser generation and laser power supply,Modular and redundant design; Compact Size,Light weight, easy to move; easy integration, stable performation, ensure the whole product stable quality

Description

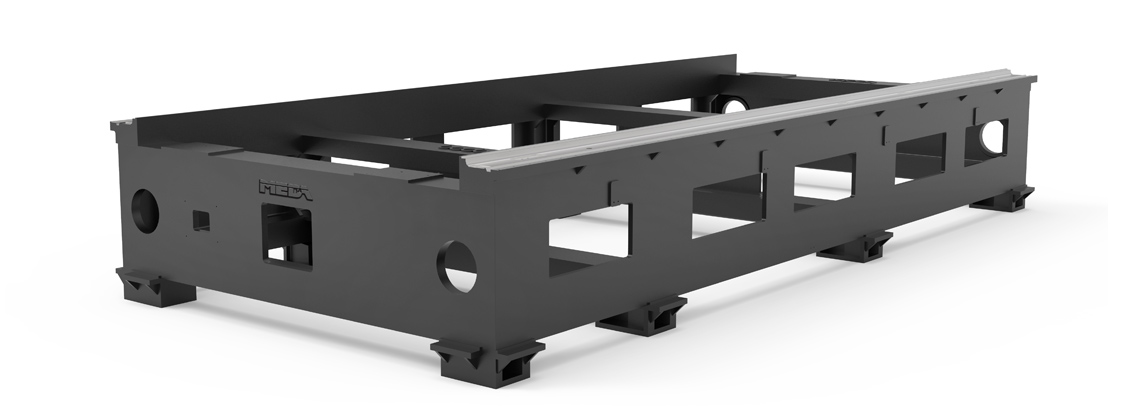

Machine base.Adopt integral cast iron bed, better stability and shock resistance, higher cutting quality.

The focus can be automatically adjusted for a variety of focal lengths

Auto focus function, capacitive sensing, automatic servo system

Composite lens, built-in water cooling structure

Collimating and focusing components of dual water cooling thermostat guarantee

Adopt drawer type lens holder, change protection lens quickly

Smooth and efficient airflow design

Suitable for all kinds of fiber lasers generation

Short and long focal length universal, can achieve the best cutting effect of thin or thick plate

All equip with the protecting lens for protecting collimating lens

The QBH circumferential position can be adjusted to ensure that each QBH red point faces outward to facilitate the plug and unplug of optical fiber head

The visual window of the focus position ensures that the input and output focus are exactly the same;

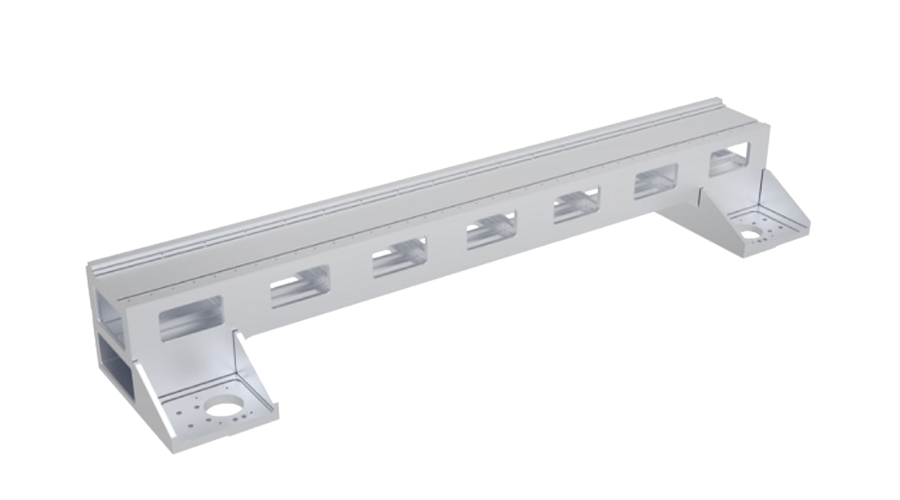

One piece gantry, more than 90 °the hardness

Professional PC ipc operation, graphical interface, convenient operation,Professional cutting control software can design all kinds of graphics and text, real-time processing, support CAD, CorelDraw and other professional drawing software.

Intelligent configuration of centralized lubrication system device, timing and quantitative forced lubrication, to ensure long-term high-precision operation of moving parts.

High standard production system.Full assembly process inspection, all the detection records are kept for customers to check at any time

electric control cabinet Equipped with temperature and humidity controller to ensure the stable operation of the electronic control system for a long time

Equipped with wifi wireless control, remote diagnosis can be achieved, greatly reducing the waste of time and money caused by the round trip of personnel: by looking at the laser parameters, analysis of the laser fault cause;Check whether the cutting process parameters are wrong through the control system software, and troubleshoot the cutting faults.

Big encircle design with mobile network video to monitor the processing area without dead Angle in real time, and realizes the perfect combination of mobile phone remote monitoring and real-time monitoring of machine tools.

High power double cooling water cooler (can refrigerate laser and laser head at the same time).With perfect cooling system, the machine runs stably, efficiently and endurable

The imported electric proportional valve provides a strong foundation for the machine to operate for a long time with high precision

| Model | MD3015FE | MD4020FE | MD6015FE | MD6020FE | MD6025FE |

| Max cutting area | 3000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6000*2500mm |

| Power r | 1kw, 1.5kw , 2kw , 3kw , 4kw | ||||

| Optional Laser source brand | Maxphotonics , Raycus , IPG | ||||

| Applied materials | Carbon steel , stainless steel , inox , copper , brass , aluminum , zinc | ||||

| Lathe | One piece cast iron ( HT250 Raw material ) | ||||

| Laser head | Auto Servo focus OSPRI | ||||

| Advantage | Improve working efficiency , One table is doing cut job , Another table is doing unload &load | ||||

Metal materials such as Carbon steel, Stainless steel, Aluminum alloy, Titanium alloy, Galvanize sheet, Brass, Red copper etc.

For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing.

Chat online